The Technical Secretariat and PEFCR project

The Technical Secretariat is the guiding body that is developing the PEF Category Rules (PEFCR) for the apparel & footwear industry. It is made up of representatives of various stakeholders including brands (about 50% of the European market), fibre and textile sectors, NGOs, scientific experts, and governments to ensure different perspectives in the decision-making process.

Until the end of the PEFCR development process is reached, mid-2024, the PEFCR is still a work in progress and will be updated by the Technical Secretariat based on agreements between members, comments received during public consultations or expert reviews, or guidance from the Technical Advisory Board (TAB). After 2024, the Technical Secretariat’s mandate will be over, and a new Technical Secretariat would have to be created to integrate future changes.

The adoption of the apparel & footwear PEFCR will enable reductions in the cost of individual studies, as it will facilitate PEF studies. The rules will be publicly available on the European Commission website, meaning there will be no need to create assumptions from scratch for each study. Also, following a common calculation framework will make it easier to build on studies of other products in the company’s own portfolio and, from an innovation perspective, to build tools to automate LCA studies in the near future.

The PEF is a methodology giving a standardised framework to assess products’ environmental impacts. It is not a law and doesn’t impose anything on companies by itself. But the methodology will facilitate the assessment of each product for companies.

For internal purposes and assessments, there is no need for third-party verification. The studies can be managed internally by companies. However, for any external communications, third-party verification is required following the PEF methodology.

This area continues to be a work-in-progress for the Technical Secretariat. For the lifetime, the concept of the “duration of service” from the Higg Product Module (PM) methodology is used. The PEFCR focus is on the intrinsic quality of the product and its materials, as measured with standard physical tests, the repairability potential of the product and design, and other non-physical aspects.

Required Data

*Note that the list of mandatory data and their requirements is likely to change with PEFCR iterations, until the adoption of the final PEFCR in 2024. This section can be updated accordingly*.

The PEFCR is mandating company-specific data points (i.e., product- and supply chain-specific) that have to be collected for each stage of the life cycle.

All other data points are considered “secondary data”, meaning they are generic and can be found in the PEFCR.

PEFCR users will not be asked to create datasets from scratch, the EF 3 database will provide a large number of relevant datasets. Users of the PEFCR will have to select the most relevant dataset based on the primary data collected (what is actually used for the production of this garment) for LCS1 and LCS2, and use primary data collected for energy and transport if desired. Companies can also decide to create new EF-compliant datasets fully based on primary data if they wish.

Mandatory company-specific data include:

- Life cycle stage 1: raw materials (not including packaging)

- Raw material production (not including packaging) and type and weight per unit of material including trims and material provenance (distance and provenance share). Example: composition, origin or production steps, etc.

- Raw materials transport (including empty return) Example: mass transported, mode of transportation, distance travelled for each material (including empty return)..

- Option 1: If the exact location of the supplier is known, as well as the transport mode (e.g. the specific type of truck, ship and train or plane), the specific data available shall be used.

- Option 2: In case the exact location of the supplier is known as well as the transport mode, but the specific type of truck, ship, train or plane is not known, the specific data available shall be used together with the default values (including utilisation ratio) for the transport mode

- Life cycle stage 2: manufacturing

Manufacturing: processes and technologies used (i.e., spinning, weaving, dye cutting, and sewing, assembly, etc), specific location, and loss rates. - Life cycle stage 3: distribution

Distribution – air cargo only. If the company exceeds the default air cargo distances or provenance set by the PEFCR by more than 50%.Other information – Final product weight, deadstock rate, and deadstock fate.

- LCS 4 – use phase

Specific garment use instructions shall be followed for leather and fur products. - LFS 5 – end of life

No mandatory data required - Along the product life cycle

Final product weight, deadstock rate, and deadstock fate that are generated at each stage of the product life cycle. Example: shares of deadstock landfilled, incinerated, recycled and associated recycling pathway.

Providing primary information to assess the intrinsic product quality, if a product is delicate, or its repairability potential is highly recommended, but not mandatory.

Secondary data corresponds to the data that is not directly collected, measured, or estimated by the company but refers to industry averages such as statistics, other published production data, etc. The PEFCR provides default values when required, and generic datasets can be sourced from the European Commission’s Environmental Footprint (EF) 3 database.*

For example, the following default data points can be replaced by primary data for a cotton t-shirt:

Life cycle stage 1 – Raw materials – energy used to produce the cotton needed

Life cycle stage 2 – Manufacturing – energy used to knit the fabric

Life cycle stage 3 – Distribution – exact distance between the distribution centre and the place of retail where the t-shirt will be sold

Life cycle stage 4 – Use phase – Primary data cannot be used for most of the use phase, with the default data provided in the PEFCR being mandatory

Life cycle stage 5 – End of life – exact share of waste landfilled, recycled or incinerated in the countries where the t-shirt is sold

The deadstock rate and deadstock fate, assessed at each stage of the product life cycle, are part of the mandatory primary data. This enables accounting for potential loss over the entire life of the product, and not only during the manufacturing process or at the end of life.

The EF database is developed by data developers based on literature review and primary data from companies. It is verified, validated, and managed (updated) by the European Commission to ensure transparency and robustness. EF 3 database is still under development and should be finalised by the end of 2022. It is the only fully EF-compliant database and it will initially be accessible freely when used together with the PEFCR.

The PEF method follows the materiality principle – focusing only on what matters and using secondary data for the rest. For the most relevant data points (see the question “mandatory primary data” above), based on primary data, the users of the PEFCR will have to select the most appropriate dataset from the EF database. For example, companies will be asked to pick the best cotton dataset to reflect the origin and yarn size used in their products. For the rest, the default values provided in the PEFCR can be used, for example, to model the distribution pathway for a typical t-shirt. Companies can also decide to create new EF-compliant datasets fully based on primary data if they wish.

Accessibility

The PEF methodology is relatively complex as it needs to reflect the full picture of the product’s environmental footprint along the entire life cycle. Simplifying the methodology too much will risk being too approximate, moving away from proven data and ultimately not offering factual and contrasted information.

The adoption of the PEFCR should however facilitate access for SMEs. The methodology will be accessible on the European Commission website, freely, and assumptions and calculation rules will be provided, eliminating the need for companies to reinvent the wheel every time they run a study. Also, it will be easier for companies to build on previous LCAs from their own portfolio and automate LCA studies.

Implementation

A validity date will be set up when the PEFCR get published. For any update, it will be submitted to the same process as the PEFCR one: including the testing phase and public consultations

The European Commission is aligning on the requirements for external environmental claims and is developing the “Substantiating Green Claims Initiative”. We expect the initiative to specify the conditions and requirements for making environmental claims based on footprinting.

Companies can communicate the results of their PEF studies if they have gone through the PEF verification process. By default, the PEF methodology allows some claims such as comparing your product to the benchmark or to other products within the same product category. The Technical Secretariat is still discussing communication types.

What is measured via the PEF?

The Product Environmental Footprint (PEF) assesses the impact at the product level. Therefore it does not consider the production at the company level. To look at the total production from a company they would need to perform a corporate footprint.

The overall PEF study provides an aggregated single overall score in absolute values expressed in point

Each impact category result is communicated using its own unit:

- Climate change: kg CO2-eq

- Ozone depletion: kg CFC-11-eq

- Human toxicity, cancer: CTUh

- Human toxicity, non-cancer: CTUh

- Particulate matter: disease incidence

- Ionising radiation, human health: kBq U 235 -eq

- Photochemical ozone formation, human health: kg NMVOC – eq

- Acidification: mol H+ – eq

- Eutrophication, terrestrial: mol N -eq

- Eutrophication, freshwater: kg P – eq

- Eutrophication, marine: kg N -eq

- Ecotoxicity, freshwater: CTUe

- Land use: pt

- Water use: m3 world -eq

- Resource minerals and metals: kg Sb – eq

- Resource use, fossils: MJ

Renewable materials are included in the PEF method with specific modelling rules for biogenic carbon (e.g. coming from biomass). (Carbon emissions to air from renewable sources (also called biogenic carbon) through combustion, composting, landfilling etc is not included in the environmental footprint calculations as it will be reabsorbed from the atmosphere through photosynthesis during biomass growth.)

Recyclability is fully covered by the Circular Footprint Formula (CFF), created by a scientific division of the European Commission, the JRC.

Biodegradability is partially covered both by the CFF (composting) and specific toxicity and ecotoxicity modelling rules. Other advantages of biodegradability like lower microplastic pollution cannot be considered within the LCA method today as its impact is difficult to assess accurately.

Social aspects: As per its name, the Product Environmental Footprint measures the environmental impacts of products from a scientific perspective.

Microplastic pollution: The methodologies to assess microplastic pollution and plastic leakage are still under development. The PEFCR is considering options to include this aspect in future versions of the PEFCR before the final Commission adoption.

While the impact of human activity associated with each material is measured in a consistent way, natural fibres and synthetics both have a significant impact in different areas across their life cycle.

- Synthetic fibres pose a challenge at the end of their life as they cannot biodegrade, and plastic stays in the environment for an extremely long time. The impact of microplastic pollution generated over the product life cycle is difficult to assess accurately today. To be noted, while the impacts of forming non-renewable raw materials (i.e., oil or natural gas) are not counted because they occurred millions of years ago (following the current IPCC accounting approach), the extraction of fossil resources is included,and the “fossil resource use” indicator in the LCA method takes into account that fossil resources are finite, contrary to the resources for natural fibres.

- Natural materials, while inherently more circular and biodegradable, have high impacts in other areas like land use and water consumption linked to agricultural practices. To be noted, while the past impacts of agriculture are not accounted for in LCA (deforestation, beyond 20 years, biodiversity impacts of the domestication of animals), the impacts of forming renewable raw materials (i.e., cotton, flax, wool, hides and skin) are counted. This is also following the current IPCC accounting approach and scientific consensus.

Glossary

EF compliant dataset: Dataset developed in compliance with the EF requirements provided here.

More information on this section on this website

Life cycle approach: Takes into consideration the spectrum of resource flows and environmental interventions associated with a product from a supply chain perspective, including all stages from raw material acquisition through processing, distribution, use, and end of life processes, and all relevant related environmental impacts (instead of focusing on a single issue).

Life Cycle Assessment (LCA): Compilation and evaluation of the inputs, outputs and the potential environmental impacts of a product system throughout its life cycle (ISO 14040:2006). More information on this section on this website.

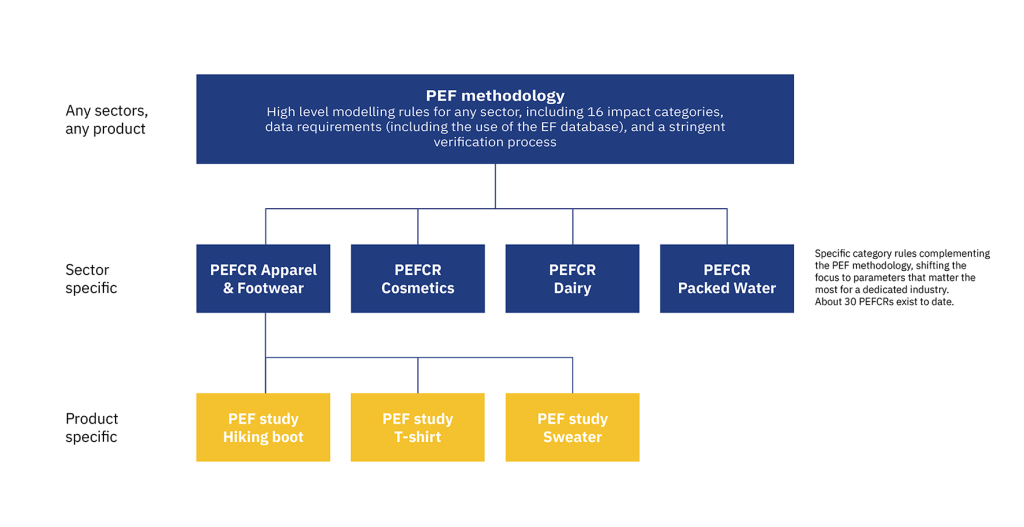

PEF Methodology: EU-recommended Life Cycle Assessment (LCA) based methods to quantify the environmental impacts of products (goods or services). The overarching purpose of PEF information is to enable to reduce the environmental impacts of goods and/or services taking into account supply chain activities (from extraction of raw materials, through production and use to final waste management). This purpose is achieved through the provision of detailed requirements for modelling the environmental impacts of the flows of material/energy and the emissions and waste streams associated with a product or an organisation throughout the life cycle. Reference

Primary data: Directly measured or collected data from one or multiple facilities (site-specific data) that are representative of the activities of the company. To determine the level of representativeness, a sampling procedure may be applied.

Product Environmental Footprint Category Rules (PEFCR): PEFCR is a product category-specific, lifecycle-based rules that complement general methodological guidance for PEF studies by providing further specification at the level of a specific product category. PEFCRs help to shift the focus of the PEF study towards those aspects and parameters that matter the most, and hence contribute to increased relevance, reproducibility and consistency of the results by reducing costs versus a study based on the comprehensive requirements of the PEF method. Only the PEFCRs listed on the European Commission website are recognised as in line with this method.

Secondary data: Data not from a specific process within the supply chain of the company performing a PEF study. This refers to data that is not directly collected, measured, or estimated by the company, but sourced from a third-party LCI database or other sources. Secondary data includes industry average data (e.g., from published production data, government statistics, and industry associations), literature studies, engineering studies and patents, and may also be based on financial data, contain proxy data, or other generic data. Primary data that go through a horizontal aggregation step are considered as secondary data.

Technical Advisory Board (TAB): Group composed of maximum 100 permanent members. The task of the TAB is to assist the Commission in relation to the implementation of existing Union legislation, programmes, and policies. It provides advice and expertise to the Commission. The issues to be discussed might include, but are not limited to, analysis of the content of newly developed PEFCRs/OEFSRs, consistency of approaches among different PEFCRs/OEFSRs, and new methodological developments seen as necessary within the EF context. Reference

Getting Terms Right